FR4 is a code name for the grade of Epoxy Glass material. Tg means Glass Transition Temperature.

Tg(Glass Transition Temperature) is one of the most important element of any epoxy and is the temperature region where the polymer transitions from hard, glassy material to a soft, rubbery material.

Printed Circuit board material must be flame-resistant. it can not be burned at a certain temperature and only be softened. The temperature point is called the glass transition temperature (Tg).

The higher Tg value means a higher temperature requirement during lamination. And the boards will be hard and crisp, which will affect the hole and the electrical properties.Normal PCB materials at high temperatures, not only will be softened, deformation, melting and other phenomena, but also the mechanical and electrical properties decline sharply. Normal FR4 Tg is between 130 to 140℃, medium Tg is over than 150-160 ℃, and high-Tg is over than 170 ℃.

The higher of Tg value, the better the performance of PCB heat resistance,chemical resistance, moisture resistance, stability and other characteristics.

When the working temperature reaches the melting point, that means the temperature exceeds the Tg value, the status of PCB material will be changed from glassy to liquid, which will affect the function of PCB. And this value is related to the stability of the PCB dimension. Usually, when we made with Tg ≥ 170℃ PCB material, which is called a high Tg printed circuit board. With the rapid development of the electronics industry, high Tg material is widely used in computers, communication equipment, precise apparatus, and instruments, etc.

We have got questions from customers " what TG value we should choose during manufacturing?".

It is true that people will be puzzled in different Tg value if he does not involve in the PCB manufacturing industry.

As general rule, higher Tg is better. However, it will increase the difficulty in mechanical process if the Tg value is too high and increase the raw material and manufacturing cost. So the substrate should be selected with high Tg and easy to process.

The major factor to consider which Tg material to use is the working temperature. If it is working on normal environment, less than 100°C,then you can use normal TG between 130-140°C. If it’s less than 130C/140C, then Tg 150 material is okay for your PCB; but if working temperature is around 150C, then you have to choose 170 Tg.

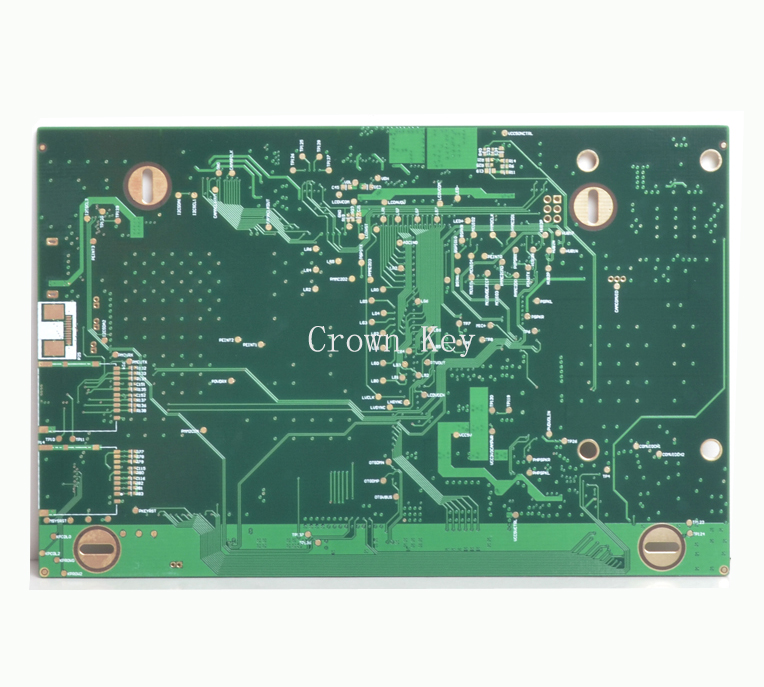

If you are not sure about what material you should choose, ask your PCB vendor for more information. The engineers from Crown Key Electronics are highly qualified and experienced, we can handle any complex PCB designs, and know both our PCB process & Capability and customers’ special requirements of PCB.